|

|

|

|

INTRODUCTION: |

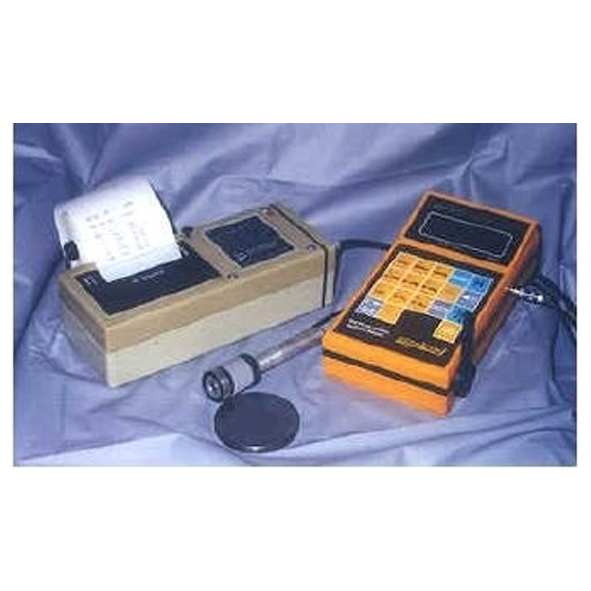

TH130 is an advanced integrated hardness tester distinguished by its very compact size, high accuracy, wide measuring range and simplicity of operation. It is suitable for testing the hardness of all metals, and widely applied in many areas of industry. |

|

|

|

|

TH 130 hardness tester combines the universal impact device D and a data processor in a single unit. It automatically computes all Vickers, Brinell, Rockwell, or Shore hardness values. The impact direction can be set so that accurate values can be achieved at any angle, even up-side down. Statistical mean value is automatically provided. |

|

|

|

|

The measuring method of TH 130 is defined as " the quotient of the impact body's rebound velocity over its impact velocity" When the tester is connected to its associated printer it can perform real time printing. It can also be equipped with optional accessories, such as support rings, to meet the requirements of specialized applications. |

|

|

|

TYPICAL APPLICATION: |

-

In situ testing of large and/or heavy components, items installed as parts of a machine.

-

During manufacture, especially of mass produced components.

-

In the stores for material idntification.

-

In locations with difficult access, or in confined spaces.

-

For quality control in general, fast and very accurate.

|

|

|

|

TECHNICAL DATA: |

| Size |

150 x 22 x 53 mm |

| Impact device |

D |

|

Impact energy |

11 N |

| Test tip |

Tungsten Carbide

Measuring |

| Accuracy |

Mean Uncertainty ± 0.8% (corresponding to ± 1HRC at HRC =58)

Max. hardness of |

|

|

|

|

|

| Sample |

980 hv |

| Weight |

130G |

| Operating time |

8 hours continuous use / rechargeable Imapct |

| Direction |

Any Angle |

| Temrature |

0 to 50' deg C. |

| Min.weight of sample |

5 Kg (less than 5 Kg to 0.1 Kg. coupled on solid support) |

| Min thickness of sample |

5 mm (coupled : 3 mm) |

| Min thickness of layers |

0.8 mm |

| Min radius of curved surface |

30 mm ( with support rings : 11 mm) |

| Coupling paste is available for testing thin or small parts weighing less than 2 Kg. |

|

|

|

|

|